Water Authority Rivierenland uses Ephyra® to improve sludge processing

Project facts

- ClientWater Authority Rivierenland

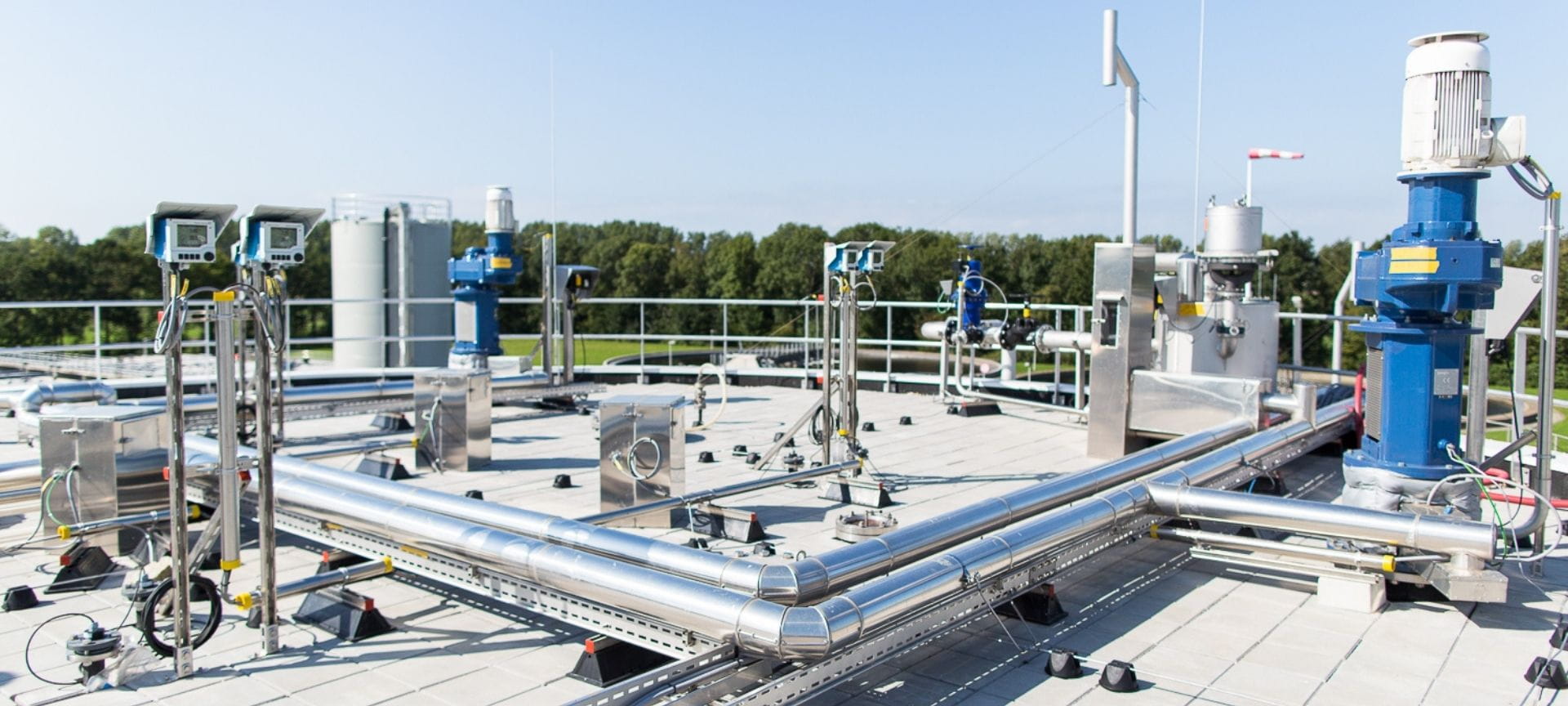

- LocationSleeuwijk, the Netherlands

- Date2019 - current

- ChallengeTo increase the capacity and sustainability of sludge processing.

- SolutionIntroduce an Ephyra sludge processing tank for more efficient anaerobic digestion, reduced waste and energy usage, and greater biogas production to power more homes.

As sustainability regulations tighten and populations expand, wastewater treatment facilities are facing growing pressure to adapt. And Sleeuwijk, in the Netherlands, was no exception. As a dedicated, regional sludge treatment hub, this plant needed an entirely new sludge treatment facility to deal both with the indigenous sludge as well as the external, imported sludges. The Water Authority selected Ephyra® as the state-of-the-art digestion technology to process more sludge, improve biogas yields for biogas upgrading and reduced sludge hauling costs, all within the smallest footprint and according to stringent planning restrictions.

The water authority, Rivierenland, worked with Royal HaskoningDHV and a group of contractors and suppliers to implement this best-in-class technology – Ephyra – to help Sleeuwijk meet increase sludge loads and its new sustainability targets.

The challenge

Sleeuwijk’s wastewater treatment plant serves a population of around 200,000 people. But the site was facing increasing pressure from a growing population, sustainability goals, and the need to achieve net zero.

It needed to significantly increase its sludge treatment facility to add capacity and create a more efficient, cost-effective digestion process.And it needed to make sure that any investments would be able to handle whatever demands the future may bring.

The solution

Rivierenland employed a group of contractors to update the wastewater treatment process at Sleeuwijk. This consortium has selected the Ephyra technology as it offered the best, most efficient and robust sludge processing for the site.

[It’s] a game changer in terms of digestion efficiency,” explains Paul Lavender, Director Water Utilities UK at Royal HaskoningDHV. “This means we maximise the amount of biogas we can recover for injection into a gas grid, and it minimises the volumes of sludge requiring off-site recycling or disposal.”

Ephyra uses a phased or staged digestion process to achieve high-rate plug-flow anaerobic digestion. This makes treatment as effective and efficient as possible. “Here, one single Ephyra tank was constructed,” says Valerie Sels, Process Engineer Wastewater Technology at Royal HaskoningDHV. “This tank consists of three interconnected compartments of about 800 cubic metres each.”

Using these three-phased – or cascading – reactors create less waste and more biogas as Merle de Kreuk, Prof. Dr. Ir. Wastewater Treatment at Delft University of Technology explains. “Particles are forced to travel through all the reactors, so they stay in the system long enough to be fully degraded.”

“Our lab and pilot experiments showed that we have higher hydrolytic efficiency in the first reactors of the cascade system,” she adds. “[That] means that we get more degradation, faster degradation, and that means more methane and less waste in the end.”

It’s not just Sleeuwijk that’s benefiting from Ephyra. The new facility also treats sludge from nine other sites in the surrounding area.

“The waste activated sludge [from Sleeuwijk] is combined with the other regional sludges and together thickened by a belt thickener which results in a sludge mixture of about 8% dry solids,” explains Sels. “Which is a lot higher than normally used in conventional digestion.”

“From the Ephyra tank, the sludge is pumped towards a post digester and a buffer to ensure that all the remaining biogas is captured and that greenhouse gas emissions are minimised,” Sels adds.

And minimising carbon emissions is considered at every stage of the process, from reducing waste to optimising energy usage. “In order to achieve net zero the digesters are heated by means of a heat pump…using recovered heat from the effluent,” explains Sels.

Higher hydrolytic activity means that we get more degradation, faster degradation, and that means more methane and less waste.

The result

Sleeuwijk now has more capacity to futureproof the sludge processing part of the wastewater treatment process as the population grows. It has also increased the amount of biogas the site can generate and inject this into the gas grid – and pushed the site closer to achieving net zero.

“[Ephyra] can process twice the amount of sludge within the same reactor volume,” Lavender explains. “And under like-for-like conditions with conventional digestion, it typically produces 20% to 30% more biogas.”

“That means more energy recovered,” he adds. “And it means less potential downstream methane emissions that can be emitted to atmosphere. It also improved dewatering and it minimises the volumes of sludge that needs subsequent recycling or disposal.”

The reduction in harmful methane emissions is a big win for the planet. And Ephyra is providing benefits to the immediate communities around Sleeuwijk, too.

“The biogas in the Ephyra process is upgraded here on site in the biogas upgrading facility where it's converted into high quality biomethane for injection into the national gas grid, says Lavender. “This provides gas for the equivalent of 1000 households in the nearby village of Werkendam.”

Want to know more or got a question?

Contact our BioResource experts!