Origins and rollout

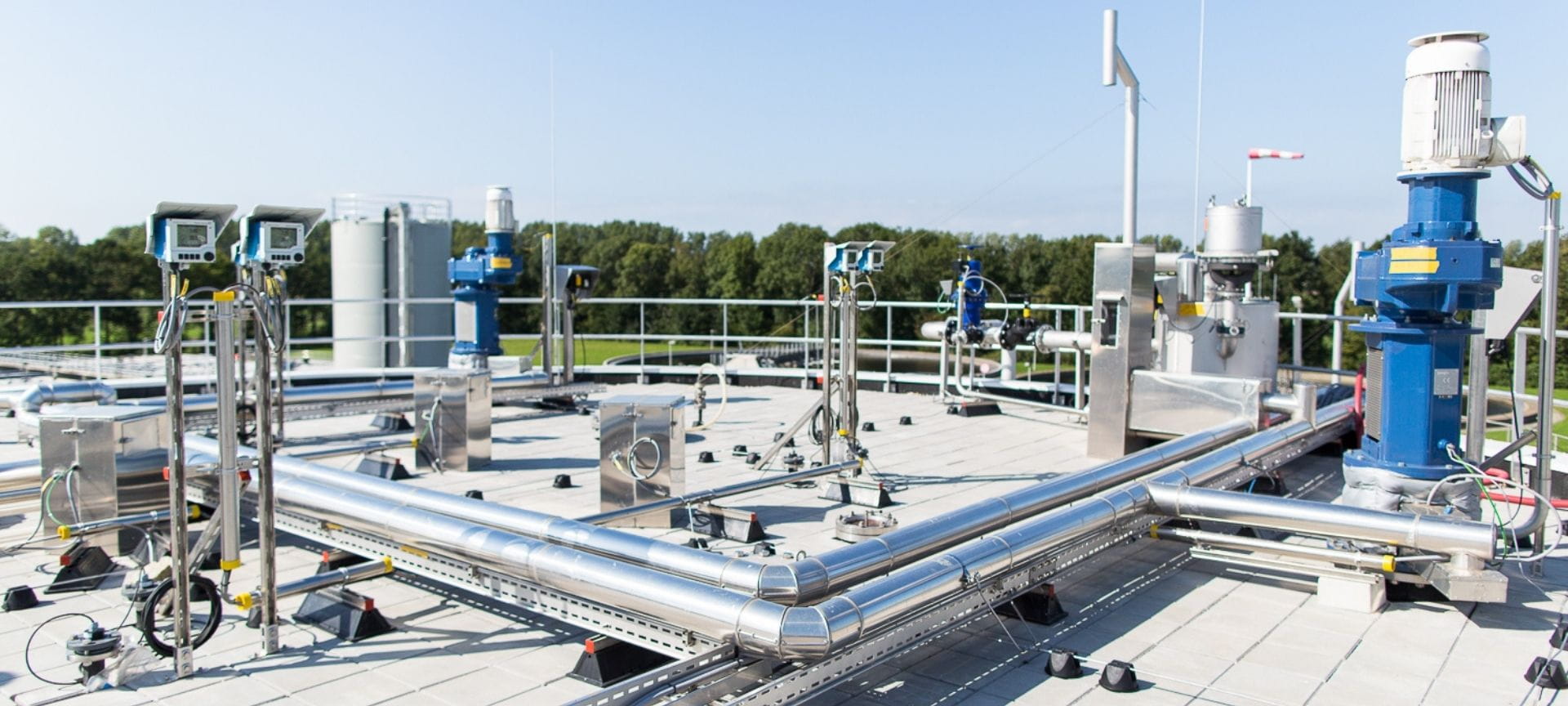

Over 10 years ago, in searching for a more affordable and sustainable route to advanced digestion, Anglian Water initially developed HpH (Heating, Pasteurisation and Hydrolysis) digestion technology and implemented it at four of its sludge treatment centres – Pyewype, Colchester, Cliff Quays and Basildon. These plants have proven to be Anglian Water's most efficient and reliable treatment facilities.

Helea® is now available to the UK water industry, supporting water companies to meet their Net Zero targets by offering a more affordable and sustainable route to advanced sludge digestion. Helea® significantly increases the biogas yield over conventional digestion. At the same time, it transforms the remaining biosolids into enhanced quality biosolids resources that can be safely recycled for agriculture as a nutrient and a soil conditioner. The process reduces both operating costs and the carbon footprint associated with sludge treatment.

The process

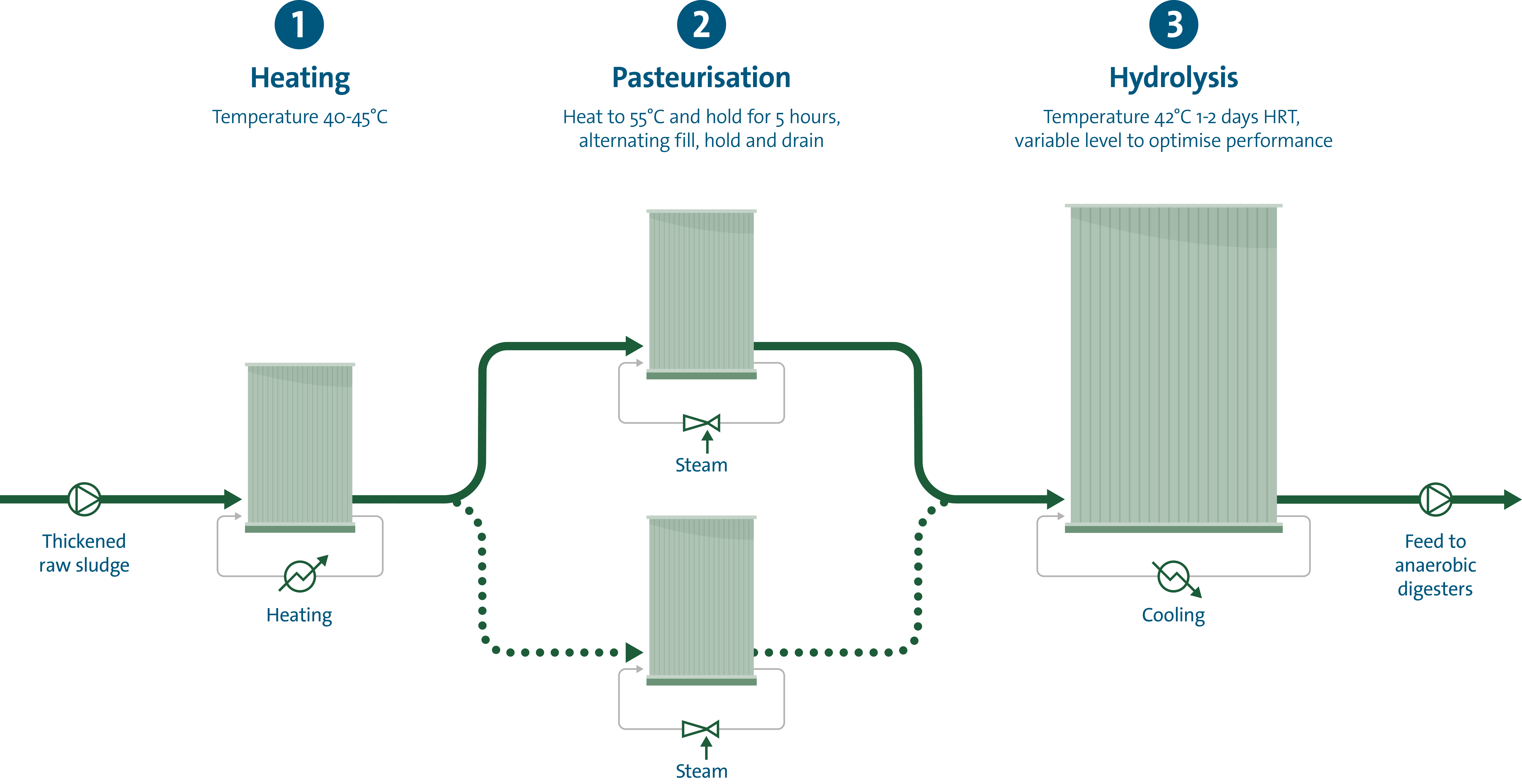

Helea® is a simple and reliable three-stage process, involving heat recovery, pasteurisation and biological hydrolysis. Effective integration of these steps with specially developed process monitoring and control features has resulted in industry-leading levels of availability, safety, flexibility and energy efficiency.

First, the temperature of the raw sludge is raised to approximately 40-45°C, using hot water recovered from Combined Heat and Power (CHP) engines. No additional support fuel is needed, making the process energy self-sufficient and optimising carbon benefits. Sludge is pumped forward to the pasteurisation tank where it is heated to 55°C by recirculating it through a steam injector. Once the pasteurisation tank is full, the sludge feed is changed over to the second pasteurisation tank, and the sludge in the first pasteurisation tank is held for five hours to achieve pasteurisation.

This sludge is then transferred to the hydrolysis tank, where it is cooled to a temperature of 38-42°C, with a retention period of typically 1.5 days, to achieve maximise biological hydrolysis, before being pumped forward to the digesters.

Helea® is installed upstream of digesters, allowing them to operate at a significantly increased organic loading rate, solids destruction and biogas yield. Helea® provides optimum conditions for pasteurisation and biological hydrolysis, with the resulting sludge more amenable to anaerobic digestion.

Future applications for Advanced Digestion

Long-term operation and performance data have confirmed that Helea® is the most sustainable, energy-efficient route to advanced digestion. Helea® provides the benefits of advanced digestion, with increased sludge capacity for existing anaerobic digestion plants, and maximum biogas production. Helea® has proven to be the lowest capital cost route to advanced digestion, when compared to alternative processes, such as thermal hydrolysis, and also achieves significant operational savings on the journey to Net Zero.Want to know more or got a question?

Contact our BioResource experts!