Proven crystallisation technology for purifying water and harvesting valuable resources

The Crystalactor is sustainable and cost-effective compared to other technologies like precipitation, ion exchange or membrane filtration. It produces a valuable resource, instead of a costly waste stream. The Crystalactor also has a smart controller, which reduces the chemical, operational and maintenance costs by predictive control of the pellet bed. It not only ensures a fully automated process operation, reliable performance and ease of operation but also an optimised and energy-efficient treatment. It even enables remote control plus real-time remote support.

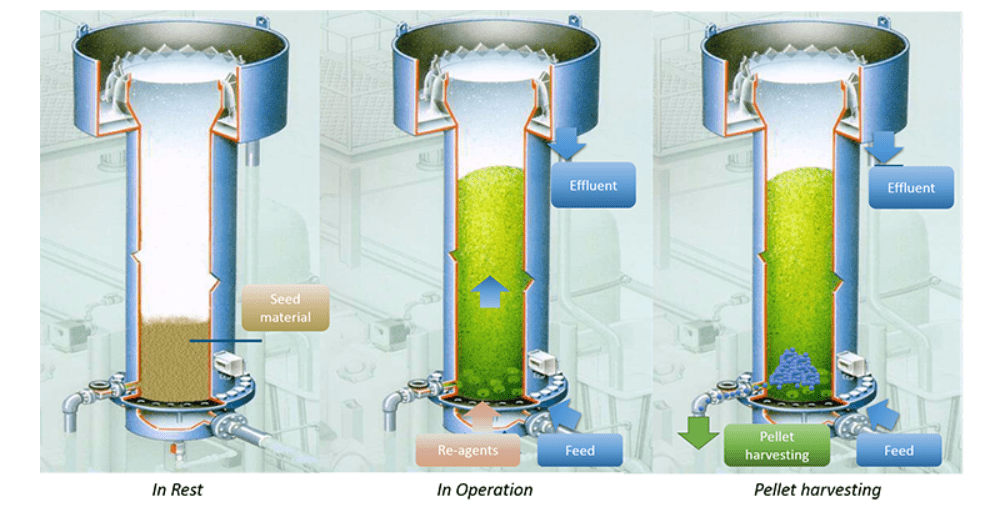

The process

The heart of the Crystalactor installation is the pellet reactor, partially filled with a suitable seed material such as sand or the target mineral. Feed water is pumped in an upward direction at a superficial velocity of about 40-100 m/h, depending on the application. To crystallize the target component(s) on the pellet bed, a driving force is created by a reagent dosage and for pH adjustment and/or reaching supersaturation. By selecting the appropriate process conditions, co-crystallization of impurities is minimised, and high-purity crystals (pellets) are obtained. The pellets grow and move towards the reactor bottom by gravity.

Research and practice have demonstrated that maximizing the specific surface (m2 pellet surface per m3 reactor volume) near the reactor bottom is the key to the successful operation of the pellet reactors. This requires an integrated approach and control of the hydraulic load, reagent dosing of base and supersaturation.

Intermittently, a quantity of the largest fluidized pellets is discharged from the reactor and fresh seeding material is added. After atmospheric drying, readily handled pellets are obtained and the need for sludge dewatering, drying or hauling of sludge is eliminated. These pellets can be transported for reuse and/or commercial resource recovery, which contributes positively financially to an overall business case.

The benefits

Process robustness, which leads to significantly reduced operator attendance, less maintenance and higher capacity availability

Optimised process performance, leading to savings in operational costs for back-washing of downstream carry-over filters

Easy operation and reduction in ‘spend hours’ of operators

The operational benefits

Waste to revenue: The unique capability of the Crystalactor is its ability to harvest water-free crystals, also referred to as pellets. High-purity pellets have commercial value in many applications such as agriculture and fertilizers, cement manufacture, chicken feed, composite materials etc.Sustainable: Crystallization is more sustainable compared to conventional treatment processes such as chemical precipitation, ion exchange (IX) and reverse osmosis (RO). Crystalactor produces water-free pellets, eliminating troublesome and costly sludge dewatering units. Chemical consumption of the Crystalactor is comparatively low compared to other technologies and the pellets can be reused.

Smart technology: The Crystalactor is provided with Smart Control, an advanced control system that applies self-learning algorithms to predict and control the crystallization processes.

Cost-effective: Lower capital costs due to lean and cost-effective design, and lower operational costs.

Applications

Softening: Crystalactor removes calcium from water in the form of calcium carbonate pellets, by dosing lime, caustic soda or soda ash as reagents. The calcium concentration can be reduced to typically 20 mg/L as Ca (0.5 mMol/L; 50 mg/L as CaCO3).Fluoride recovery: Crystalactor also removes fluoride from water in the form of calcium fluoride pellets by dosing lime, or a combination of caustic soda and calcium chloride as reagents. The fluoride concentration can be reduced to below 10-20 mg/L. The bulk of the fluoride is removed in the form of calcium fluoride pellets from the reactor and filtration is usually applied to polish suspended calcium fluoride flocs that are present as carry-over from the reactor.

Phosphate recovery: Crystalactor removes phosphate from municipal or industrial wastewater in the form of calcium phosphate, magnesium phosphate, vivianite or struvite (magnesium ammonium phosphate) pellets by dosing lime or magnesium hydroxide, or a combination of caustic soda and magnesium chloride as reagents.

Heavy metal recovery: Crystalactor removes precious metals from industrial wastewater as metal carbonate or hydroxide pellets by dosing a combination of caustic soda and soda ash as reagents. The metal concentration can generally be reduced to below 1 mg/L. The bulk of the metal is removed in the form of pellets from the reactor. Effluent filtration is usually required to remove suspended flocs that are present as carry-over from the reactor.

Brine management: IDE Technologies Israel developed a new technology MaxH2O DESALTER for Brine management, making it the perfect solution for the mining and power-generating industry. The semi-batch RO system contains an integrated salt precipitation unit (Crystalactor) for continuous desaturation of RO brine. This innovative system overcomes variable changes in the feed flow and composition, resulting in very high recovery without reducing the membrane cross-flow.

Crystalactor plants

Currently, there are more than 70 Crystalactor plants in operation or under construction across the globe.ReinoutVreugdenhil

Product manager Crystalactor