Our history

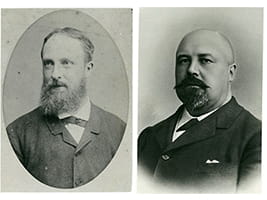

Our history begins in 1881 when two young and ambitious engineers Johan van Hasselt and Jacobus de Koning set up the first independent engineering firm in the Netherlands. The journey continued when, some decades later, three civil engineers Dwars, Heederik and Verhey started their firm the Vereenigde ingenieursbureaux voor bouw- en waterbouwkunde in 1917. Both companies joined forces in 2012 as Royal HaskoningDHV.

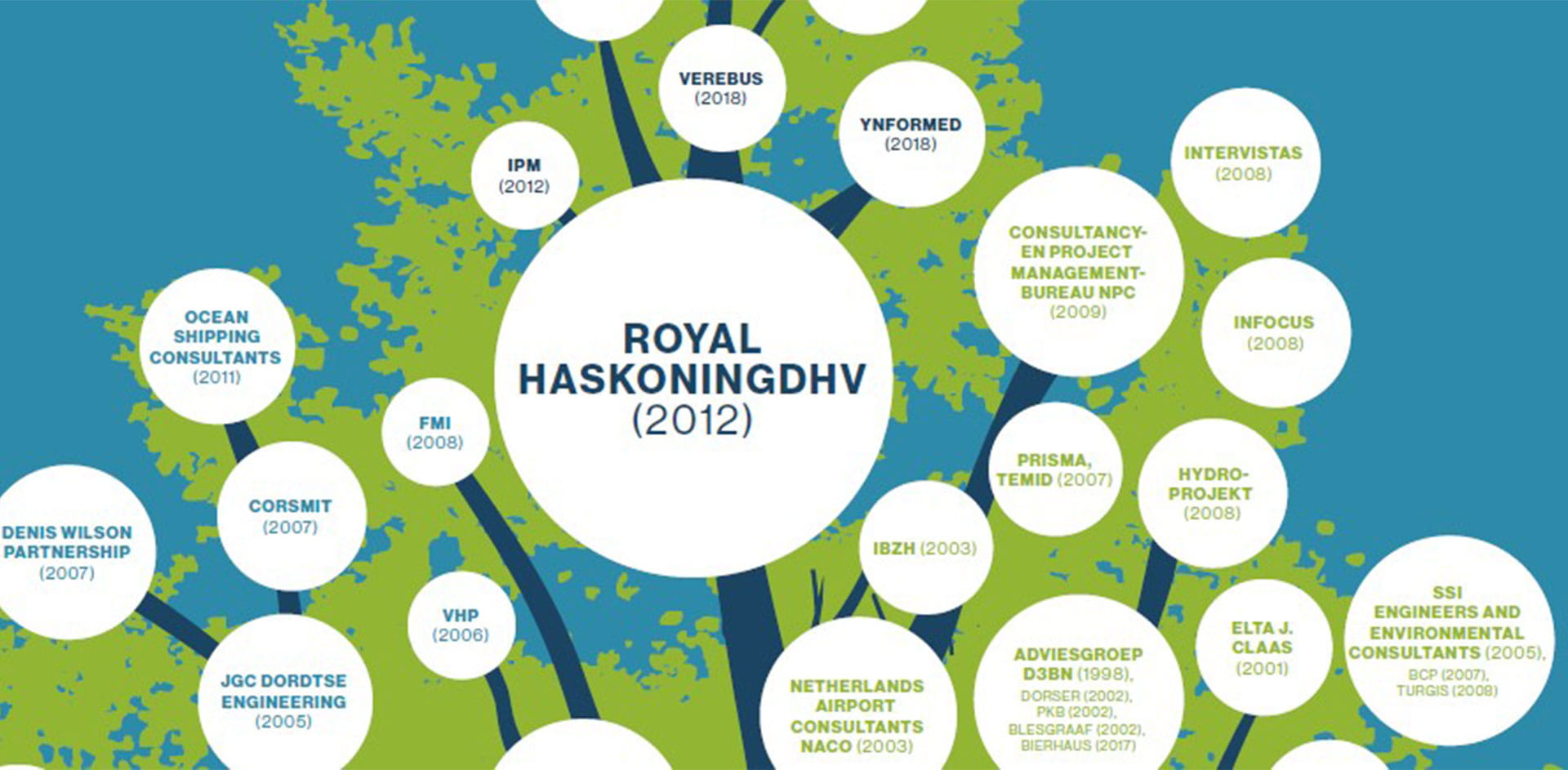

Our family tree

Our founders shared a passion for the profession of engineering, an indestructible belief in progress and the drive to make the world a better place. This is still in our DNA today. This family tree (dated 2021) shows how we have grown from a small passionate group of people to the international community of 6,000 employees we are today.

Key moments in our firm’s history

2021

Royal HaskoningDHV celebrates its 140th anniversary. Much has changed over the years, but we remain focused on enhancing society together with the same perseverance and ingenuity as our founding fathers displayed. Nowadays it’s with the support of the latest digital solutions.

1994

Engineers and environmental scientists of British engineering consultant Posford Duvivier joined our company. Their specialist expertise working on port installations represented a major expansion for our company.

1951

Our company entered a golden era of prosperity and growth when we joined Nedeco, Netherlands Engineering Consultancy. This umbrella organisation for overseas projects provided a wealth of experience and laid the foundations for further international expansion.

1940

During the Second World War, DHV made a valuable contribution to the national food supplies in the Netherlands by designing dozens of so-called Centrale Keukens, or community kitchens.

1919/1968/2005

From 1919 onwards, DHV provided advice on sewage systems. In 1968, they invented the Carrousel to carry out wastewater treatment. And in 2005 the first fully functioning industrial wastewater treatment system based on Nereda® technology was put into use.

1917

Women started working in our company. Their role changed dramatically in more than 100 years since they started.

1917

A collaboration with a Dutch beer brewer lead up to the start of engineering firm Dwars, Heederik & Verhey (DHV).

1889

Jacobus de Koning travelled to Egypt to create a design for a railway bridge across the Nile.

1881

Johan van Hasselt and Jacobus de Koning set up the first independent engineering firm in the Netherlands. It’s the only engineering firm in the Netherlands that has been able to keep its independency until today.Images

1881, 1917, 2021: Company archives Royal HaskoningDHV1889: H. Arnoux, Koninklijk Instituut voor Taal- Land- en Volkenkunde

1917: Heineken collection

1919: Stadsarchief Amsterdam/Gustaaf Oosterhuis

1940: Historisch Centrum Leeuwarden

1951: Nedeco archives

1994: Steve Cadman/Flickr, Creative Commons