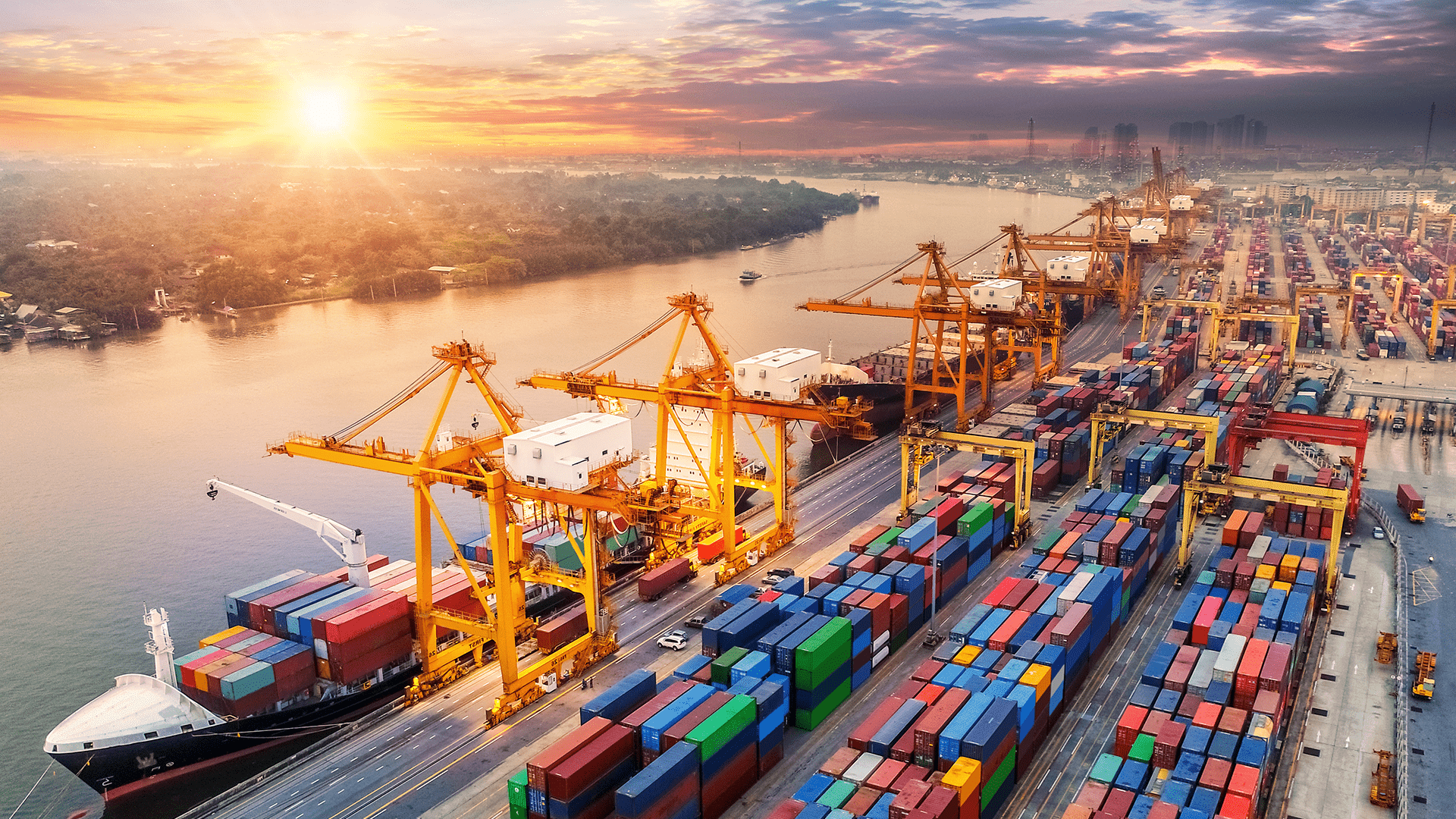

Container Terminals

Container terminal planning: adding value

With the right container terminal consultant, you’ll benefit from high-quality, cost-effective, robust solutions – and an expert who can support and advise you at every stage.

Since designing the UK's first purpose-built container terminal in 1967, Royal HaskoningDHV has been the global leader in container terminal design and engineering. We work in over 100 countries, on projects ranging from small-scale developments to international mega-hub ports.

Our market intelligence and knowhow mean we can find the right solutions to suit your specific terminal. We’ll also deliver technical excellence – incorporating digital ways of working into all our container terminal services.

Automated container terminal design

As the need for efficiency and productivity grows, so does the drive for container terminal automation. Automated solutions can help accommodate larger ships and taller cranes while keeping workers and engineers safe. They also increase terminal efficiency by optimise operations and productivity.

We can incorporate automation into container terminal planning to intrinsically combine infrastructure and IT systems. With state-of-the-art design and simulation software like FlexSim, SHIPMA, TERMSIM, AutoCAD Civil 3D, Infraworks, Vehicle Tracking, ArcGIS, Revit and other BIM technology – as well as our in-house software – we provide the best possible service.

Our container terminal capabilities

Our specialist services cover everything from container terminal studies, market analysis, and operations evaluations to design, construction, and on-site project management.

We can provide:

- Traffic forecasting - for your terminal and the wider region

- Terminal layout plans and planning consents (permitting)

- Terminal automation

- Discrete-event simulation for container terminal operations

- Container terminal operations simulation

- Smart Ports planning and design

- Fast-time vessel manoeuvring simulation

- Static and dynamic mooring analysis

- Specification and selection of container handling equipment and quay furniture

- Planning and supervision of dredging and reclamation

- Design of quay foundations and structure

- Above and below-water inspections and rehabilitation design

- Design of terminal facilities and topside infrastructure

- Terminal gate, yard and rail yard planning and civil design

- Mechanical and electrical design, including cold ironing

- Planning of navigation channels and design of navigation aids

- Technical, safety and security appraisal

- Environmental impact assessment

- Independent checking engineer

- Lenders technical advisor

- Technical and commercial due diligence

- Supervision and project management of implementation

Maritime challenges

To create future-proof maritime facilities that will continue to thrive for decades to come, you need a combined digital, sustainable, and climate resilient strategy.

Learn more about what we can do for you:

- Digital transformation in ports, terminals, and shipyards

- Leading sustainability in ports, terminals, and shipyards

- Maritime climate adaptation and resilience

Our offerings

The drive to improve performance, energy efficiency, environmental standards and safety are ever present. Constraints over costs and timings add to the challenge. Find out how we can support with the challenges you are facing.

Discover why we’re the first port of call for:

Sectors we support

We are global maritime consultants specialised in the planning and design of marine facilities, ports and terminals, and shipyards.

Find out more about the sectors where we deliver our expertise: